About the company

In the PCB manufacturing and assembling the company, Ray PCB is the best one. The company was established in the year 2005. This company produces the double-sided and multilayer printed circuit boards. The company has experienced in the over ten years in the electronics manufacturing circuit boards, fabrication works, and component sourcing services. The company genuine outstanding customer services with the teamwork and technical support has made the company in the world no one in the assembling and manufacturing business. The company takes care of the full process like PCB assembling, testing, and manufacturing the printed circuit boards with 100% pure components, and monitoring the quality of the final assembly. For better service Please see this link https://www.raypcb.com/

The company has own electronic laboratory.

In the electronics lab, the company assembling done in the lab full PCB assembly board with testing, and then deliver to the customer. The customer can also view the lab and verify the company research and development process, company engineers also help you. The company buying the latest testing instruments.

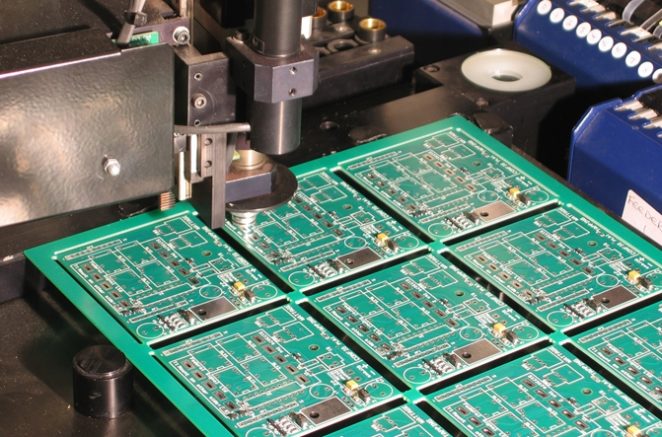

PCB assembling equipment

The company s PCB assembling equipment can handle and maintained by the experience of staff members in the field. The company staffs are the backbone of the company and provided the services in world-class techniques.

In the PCB testing lab

The high-quality PCB product is tested in the lab at first levels the company giving the 100% electronics testing and have the chemistry lab and physics lab and has the inner x-ray registration tester, CVS machine for brightener, and leveler analysis.

Circuit board fabrications following services are done.

To manufacturing the multilayer PCB, in the electronics system the multilayer boards user’s or

High, this type of multilayer PCB is faster, smaller and powerful.

Fabrication work on the PCB

In the PCB fabrication service, the company gives the high quality with the low price of the printed circuit boards. The board is a prototype or a single type. This production technology needs various technologies and materials. The company controls the multilayer printed boards and HDI PCB’s boards.

Printed ceramic boards

The ceramic material has the high thermal conductivity and low expansion coefficient factor so that it has an advantage over the normal boards. The multilayer ceramic boards have a less complex design and their performances are increased. The ceramic boards are operating at 360 degrees Celsius. The ceramic has the quality like high frequency, no water absorption and it can make with smaller size.

The PCB small prototype

In the prototype, fabrication works the PCB layout design PCB assembly and prototype fabrication are done. The company gives service in 24 hours and printing board’s gives as 12 hours depending upon the customers required. The experienced team members gave assistance to the customer’s requirements. https://www.raypcb.com

The advantage of the flexible printed boards

The circuit boards are designed with smaller in size with flexible and high density. In the mounting designing, the assembly process is very simple the flexible printed board is coated with a copper circuit with polymer printer thick film. The flexible circuit boards give an excellent and good performance. These boards have excellent thermal conductivity; low dielectric electric allows signals with a high melting point. The reason for using the flexible circuit’s boards gives the uniform electrical character.

- Its weight is low and it occupies less space.

- Flexible in the service

- The thermal conductivity is more.

- To increase reliability.

- To avoid the connectors.

For the better manufacturing and assembling services go to site https://www.raypcb.com